Former Dry Cleaner – Ocean City, New Jersey

Provect-IR® – In Situ Chemical Reduction (ISCR) Reagents for Source and Dissolved Plume Remediation

Site: Former Dry Cleaner – Ocean City, New Jersey

Constituents of Interest: Tetrachloroethylene (PCE), Trichloroethylene (TCE), cis1,2-Dichloroethene (cis-1,2 DCE), and Vinyl Chloride (VC)

Project Summary

A former print shop and dry cleaner located in a residential Ocean City, New Jersey neighborhood was contaminated due to previously conducted business-related activities. Soil and groundwater were impacted with tetrachloroethylene (PCE), trichloroethylene (TCE), cis-1,2-dichloroethene (cis-1,2 DCE), and vinyl chloride (VC). Limited soil excavation was conducted inside the former dry cleaner, but elevated chlorinated volatile organic compound (CVOC) concentrations continued to persist in groundwater. The subsurface geology consisted of coarse sand to a depth of 5 feet below ground surface (ft bgs) followed by a peat layer to a depth of 8 ft bgs. Groundwater is tidally influenced with an average depth of 4 ft bgs. Reducing groundwater geochemical conditions were present at the site likely due to anoxic conditions formed within the peat layer. Additional source excavation coupled with soil mixing utilizing an in situ chemical reduction (ISCR) amendment, specifically Provect-IR®, was selected to complete source removal and ensure residual contaminant mass was addressed.

Provect-IR® is a site-specific blend of unique reagents combined into a single product that optimizes the in situ reductive dechlorination of chlorinated VOC contamination in both soil and groundwater. This technology works by promoting synergistic interactions between zero-valent iron (ZVI), hydrophilic, nutrient-rich organic carbon sources, chemical oxygen scavengers, vitamins, and mineral sources. This patented combination of natural and food-grade amendments promotes ISCR conditions for rapid and effective destruction of the targeted contaminants. Additionally, Provect-IR® is the only ISCR reagent to simultaneously inhibit the production of methane during the requisite carbon fermentation process, which promotes more efficient use of the hydrogen donor while avoiding negative drawbacks associated with elevated methane.

Figure 1: Provect-IR® Applied to Excavation

Figure 1: Provect-IR® Applied to Excavation

Remediation Plan

The soil mixing remedial program was designed by Provectus Environmental Products, Inc. (Provectus) in collaboration with Enfuse Environmental, LLC (ENFUSE). Following excavation of the shallow soil impacts, a total of 6,000 lbs of Provect-IR® was applied to the base of the approximate 700 sq ft excavated area with soil mixing conducted to ensure contact with the impacted groundwater. Injection laterals were placed within the backfill material zone as a contingency to apply additional liquid reagents if remedial goals were not achieved. The excavation and Provect-IR® soil mixing remedial program targeted three primary wells, MW-2, MW-4, and MW-8. All monitoring wells remained in-place during excavation and soil mixing activities. Backfill of the excavated area and general site restoration occurred following source removal and blending activities

Treatment Program Results

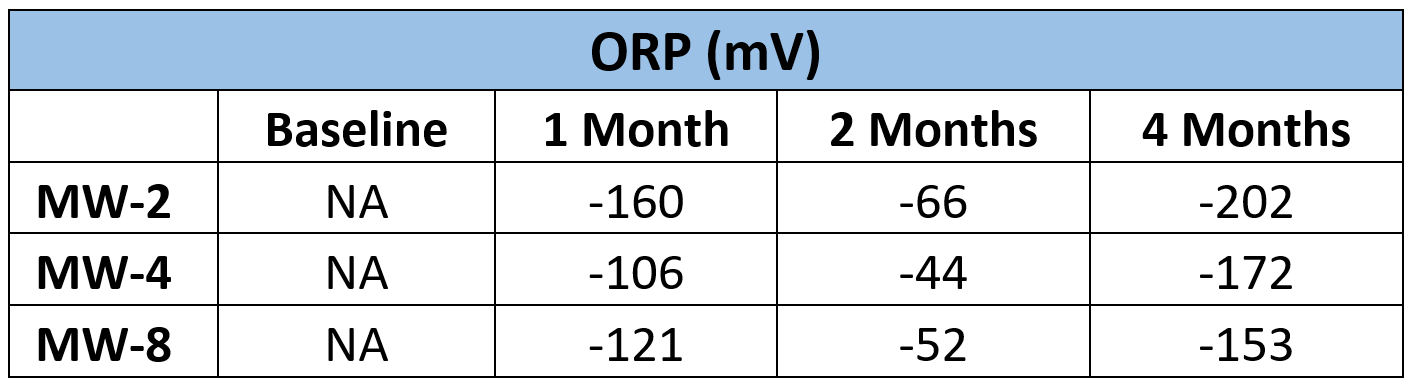

The geochemical data from the three performance wells indicate expected results and confirm successful soil blending and reagent distribution of Provect-IR® within the treatment area. Reducing conditions were rapidly observed, with reductions in DO and ORP one-month post-application. After 4 months, ORP continued to decrease and indicated strongly reducing conditions.

Table 1: ORP Data

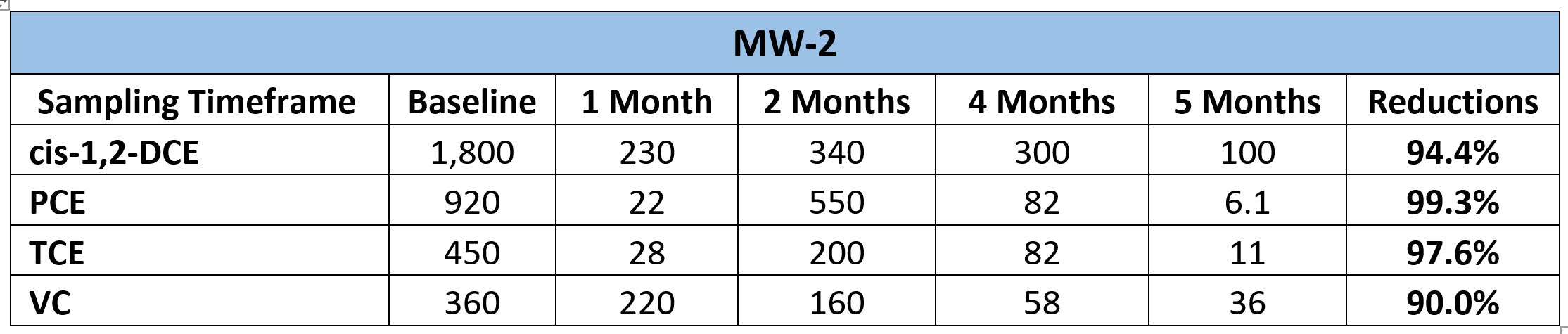

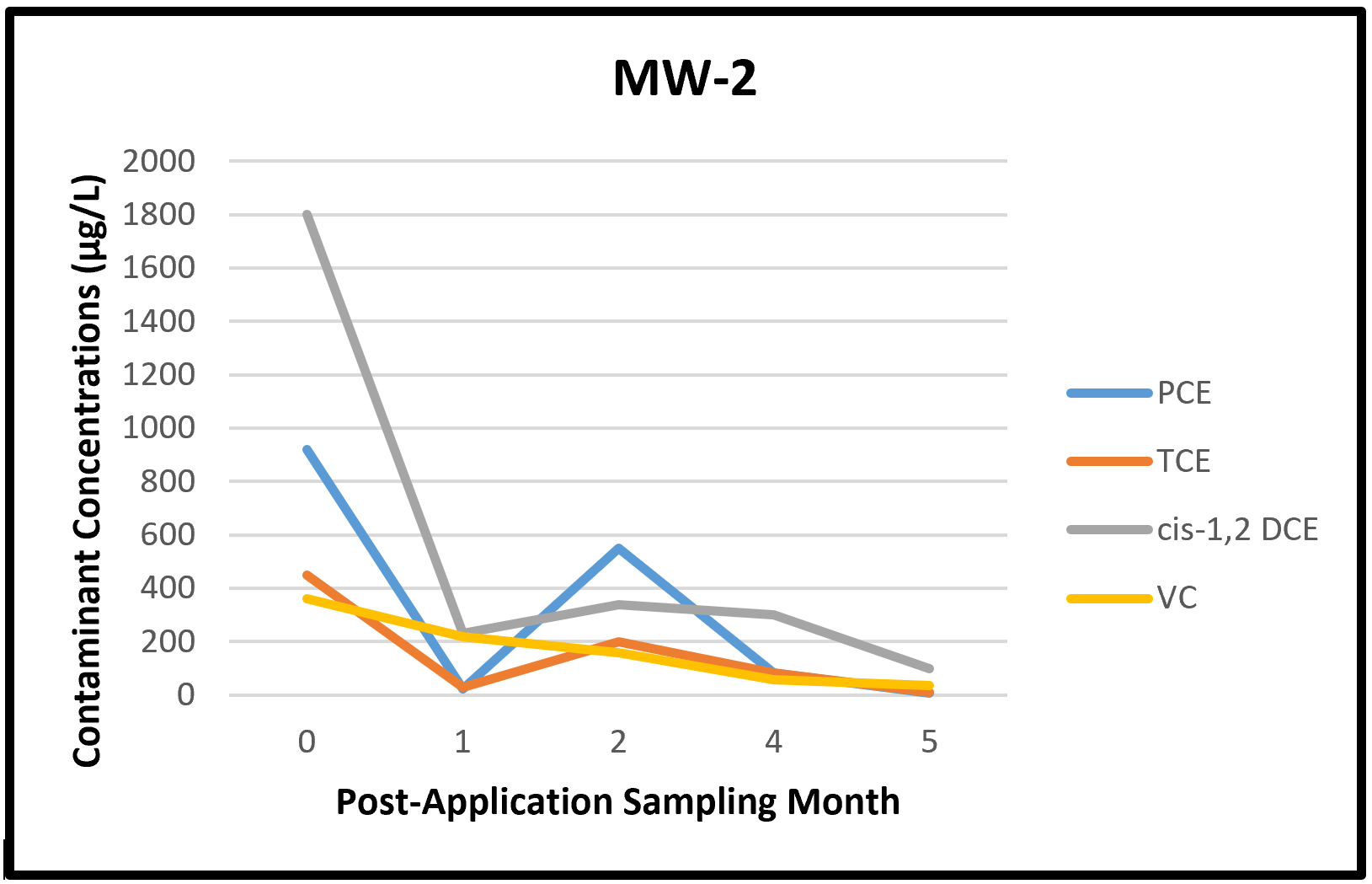

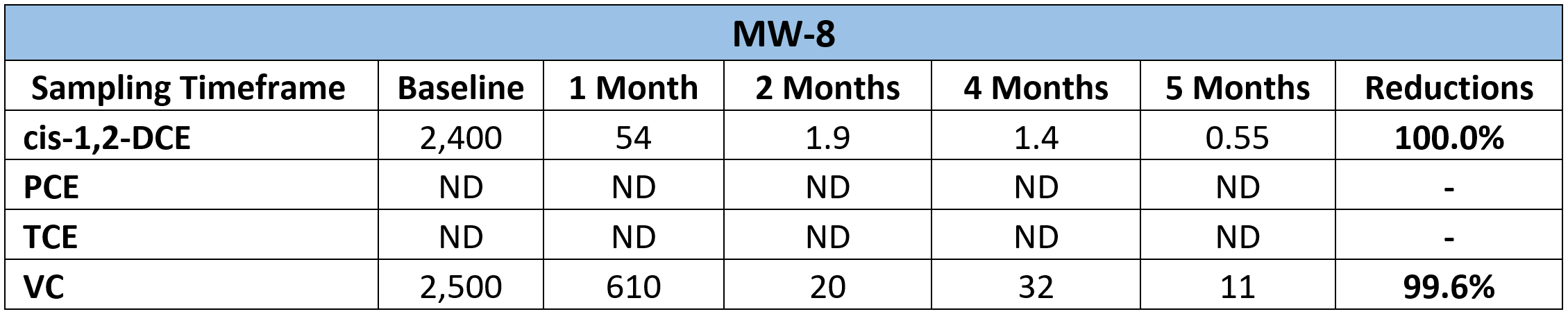

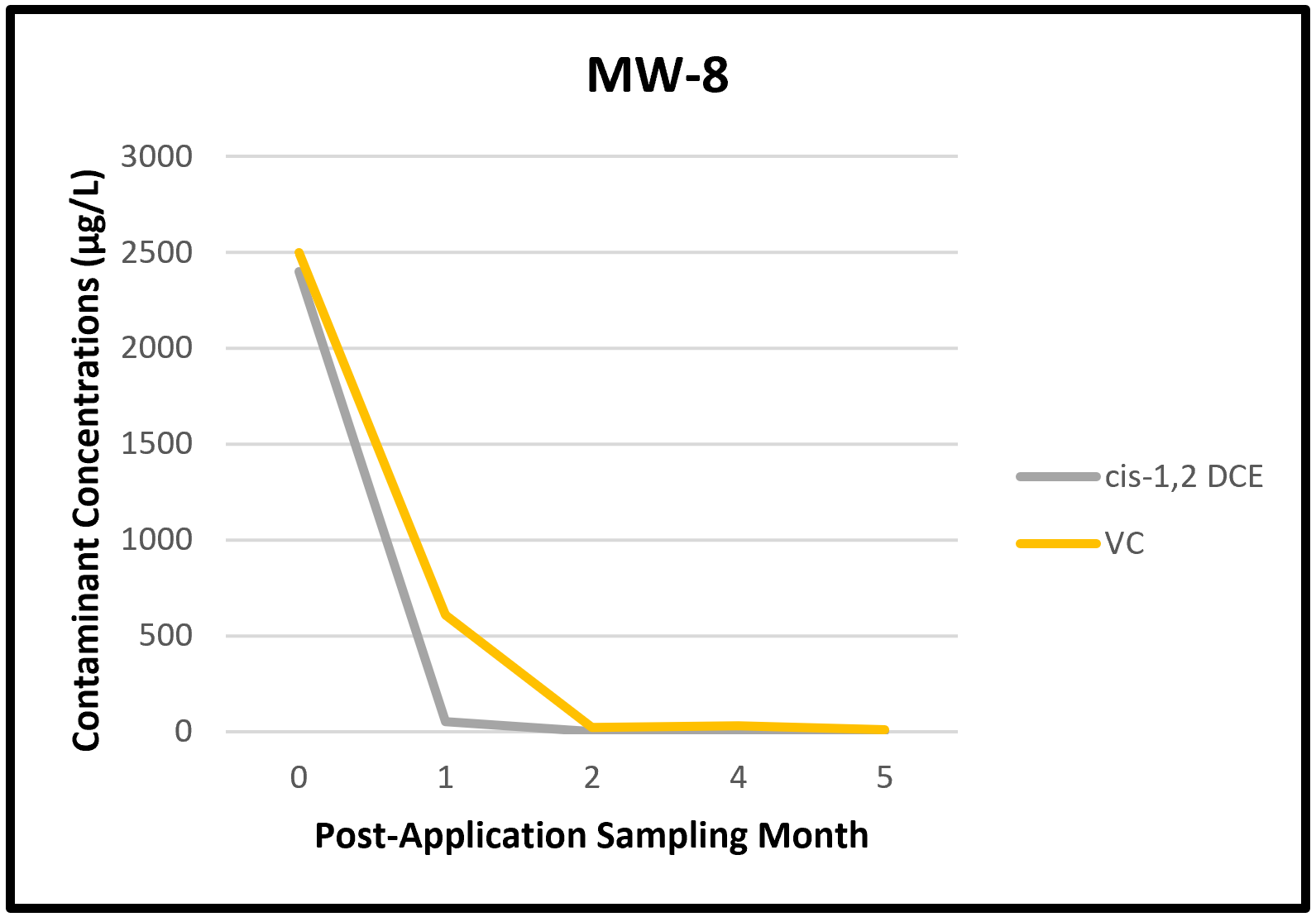

The monitoring wells with the highest VOC concentrations, MW-2 and MW-8, saw significant contaminant reductions, with each constituent being reduced by at least 90% at five months post-application. Parent compounds PCE and TCE at MW-2 have decreased by 99% and 97, respectively, while MW-8 did not have parent compounds present. Daughter product reductions at both wells range between 90% to 94% for MW-2 and greater than 99% for MW-8. Contaminant reductions at MW-4 were also significant with each individual constituent being reduced by at least 74%.

Table 2: MW-2 CVOC Data (ug/L)

Figure 2: MW-2 CVOC Data

Table 4: MW-8 CVOC Data (ug/L)

Figure 3: MW-8 CVOC Data

Lastly, small increases in ethene and ethane were observed in all three target wells, which would be anticipated and is a positive indication of remedial activity in the subsurface. No significant increases in methane were observed, which is due to the antimethanogenic reagents that are included with this site-specific Provect-IR® blend. Based on the current site geochemical conditions, it is expected that the concentrations in the monitoring wells will continue to decrease over future sampling events.

Figure 4: Soil Mixing and Injection Laterals

Figure 4: Soil Mixing and Injection Laterals

Click Here for a site evaluation, conceptual remedial design, or material cost estimate with turn-key alternatives available upon request.