Former Manufacturing Site – Pompano Beach, Florida

EZVI-CH4™ – Antimethanogenic Emulsified Zero Valent Iron (EZVI) for Chlorinated Solvent Source Area Remediation

Site: Former Manufacturing Site – Pompano Beach, Florida

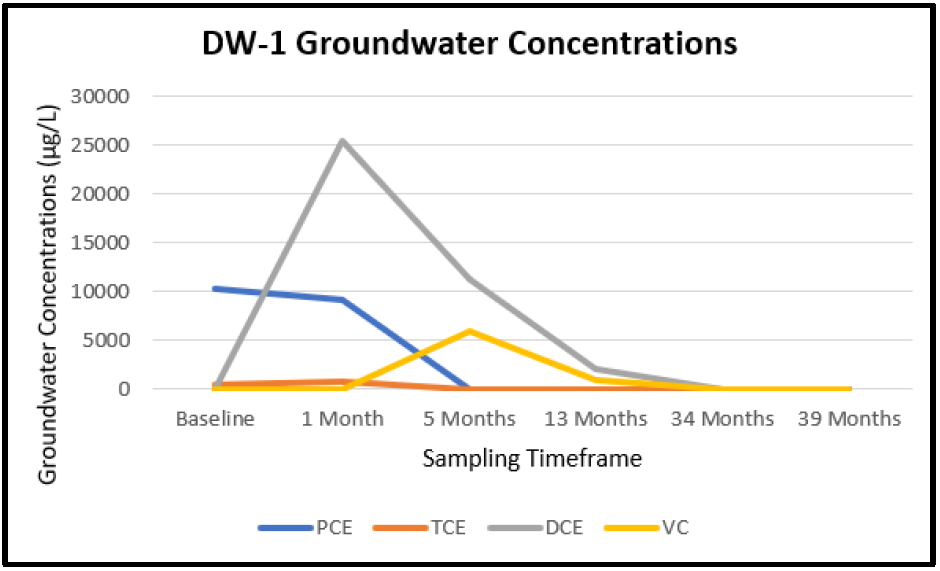

Constituents of Interest: Tetrachloroethylene (PCE), Trichloroethylene (TCE), cis-1,2-Dichloroethylene (DCE), and Vinyl Chloride (VC)

Project Summary

A former manufacturing factory located in Pompano Beach, Florida was contaminated with chlorinated solvent impacts associated with the previously conducted business operations. The site was impacted with tetrachloroethylene (PCE), trichloroethylene (TCE), cis-1,2-Dichloroethylene (DCE), and vinyl chloride (VC). Site geology is predominately sands with shallow groundwater at ca. 5 feet below ground surface (ft bgs). Previous attempts to remediate the site via in situ chemical oxidation did not achieve the target cleanup levels. Concentrations of PCE in the source area remained elevated and are indicative of dense non-aqueous phase liquid (DNAPL) conditions.

Remediation Plan

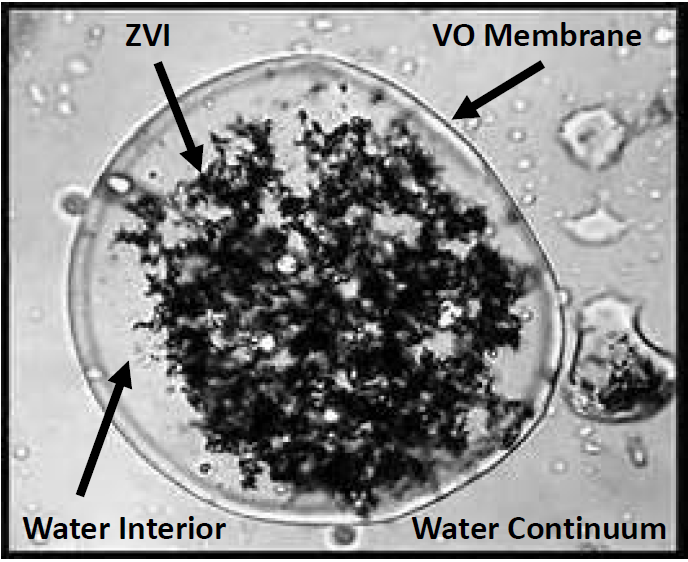

The remediation plan developed by the consultant included the use of an antimethanogenic emulsified zero valent iron (EZVI-CH4™) to primarily remediate potential DNAPL and significantly reduce the PCE groundwater concentrations. EZVI-CH4™ offers the most advanced, cost-efficient formulation of the NASA patented technology. It is an aggressive remedial technology that was developed to address dissolved, sorbed, and DNAPL level contaminated source areas using combined abiotic and biotic technologies. EZVI-CH4™ is manufactured to create a water-in-oil emulsion to ensure that ZVI powder is contained within the aqueous component of the emulsion (i.e., within the water drops). Only contaminants with a hydrophobic physical chemistry (e.g., chlorinated VOCs) will pass through the membrane and react with the ZVI. Our EZVI-CH4™ utilizes the physical chemistry of the chlorinated VOCs in the remediation process along with chemical and biological treatment mechanisms. Additionally, this proprietary blend included our antimethanogenic reagents that are designed to inhibit the production of methane and allow for more efficient use of the reagent.

The targeted source area was approximately 1,500 sq ft that included five injection wells. Initial plans included multiple injection events, though due to an unforeseen construction project on the nearby interstate, only one injection event would be completed. The initial injection event included 2,500 gallons of EZVI-CH4™ that was applied to the five injection wells. The EZVI-CH4™ injection was also supplemented with Dehalococcoides (DHC) to bioaugment the source zone. Injection depths ranged from 5 to 55 ft bgs. EZVI-CH4™ and the DHC were introduced via a specialized injection system to ensure a minimum 10 ft radius of influence and reduce the influence of lithology on the reagent distribution.

Treatment Program Results

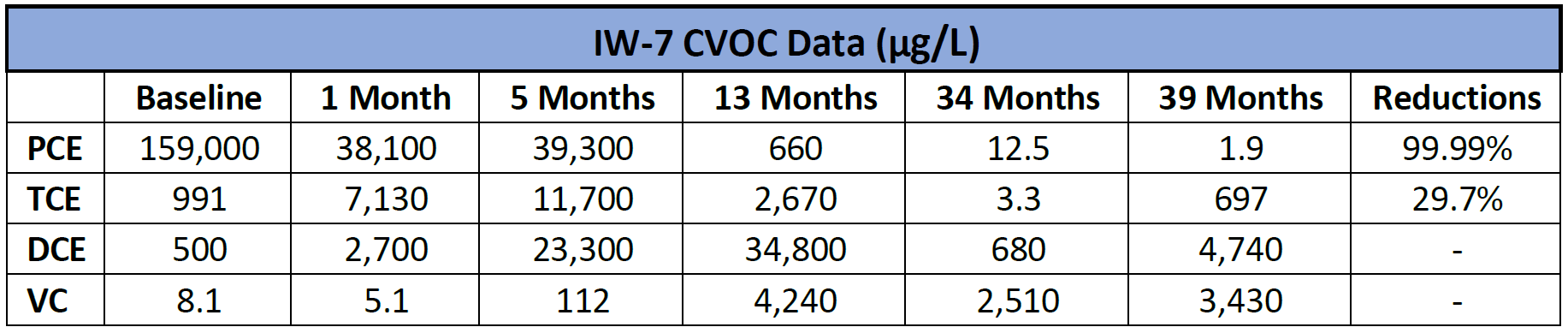

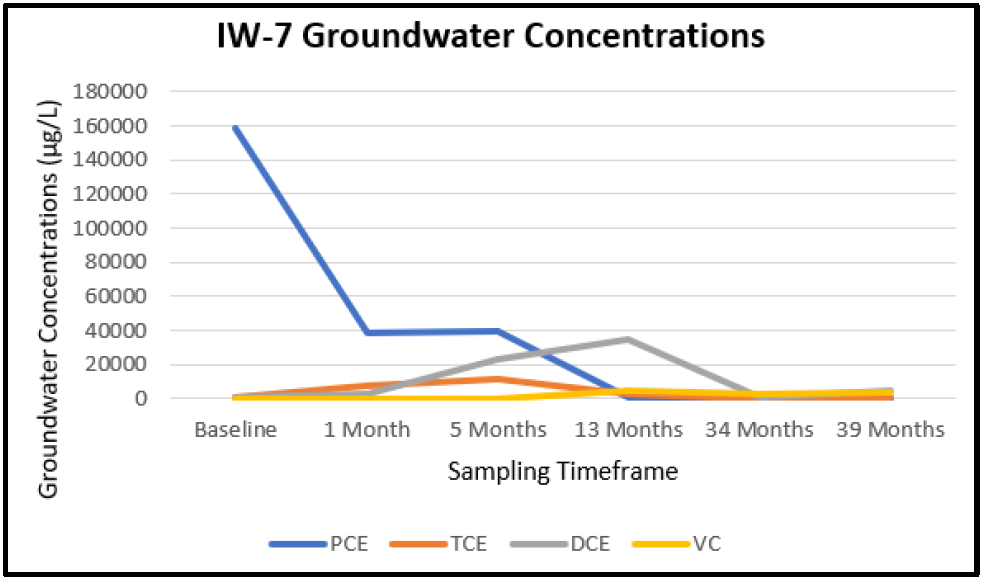

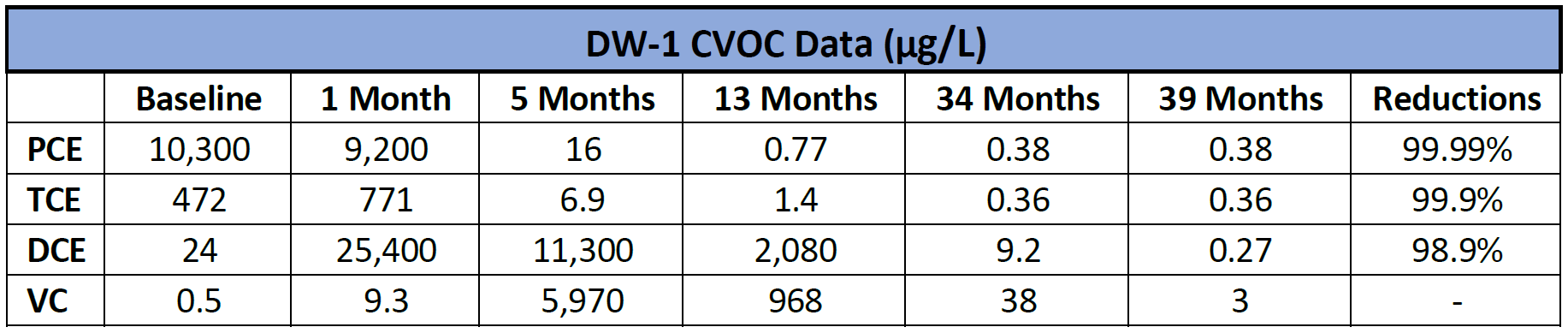

Significantly reduced groundwater concentrations within the source area indicate that potential DNAPL was remediated. PCE groundwater concentrations in IW-7 and DW-1 were reduced from 159,000 ug/L and 10,300 ug/L, respectively, to below the Groundwater Cleanup Target Level (GCTL) of 3 ug/L. Reductions of PCE in these two target wells are greater than 99.99%. Figures 3 and 4 below show a visual representation of the groundwater contaminant data for both wells, with Tables 1 and 2 further outlining the post-treatment data. Concentrations of TCE and daughter products have also started trending down. Despite only one injection event, the remediation goals of removing potential DNAPL and meeting the GCTL for PCE were achieved within the source area.

Additionally, the geochemistry for the site shows that strong reducing conditions continue to persist, with low dissolved oxygen levels and negative ORPs. Given the geochemical conditions and removal of the source area, continued contaminant reductions would be expected.

Table 1: Groundwater data from IW-7

Figure 3: Groundwater data from IW-7

Table 2: Groundwater data from DW-1

Figure 4: Groundwater data from DW-1

Please contact Will Moody at (908) 581-6291 or via email for additional information regarding this project or our technologies. Furthermore, Troy Lizer can be reached at (303) 284-7428 or via email.

Click Here for a site evaluation, conceptual remedial design, or material cost estimate with turn-key alternatives available upon request.