Former Gas Station – Point Pleasant Beach, New Jersey

Provect-OX2™ – In Situ Chemical Oxidation + Enhanced Bioremediation for Contaminant Mass Destruction

Site: Former Gasoline Station – Point Pleasant Beach, New Jersey

Constituents of Interest: BTEX, Trimethylbenzenes, and TICs

Project Summary

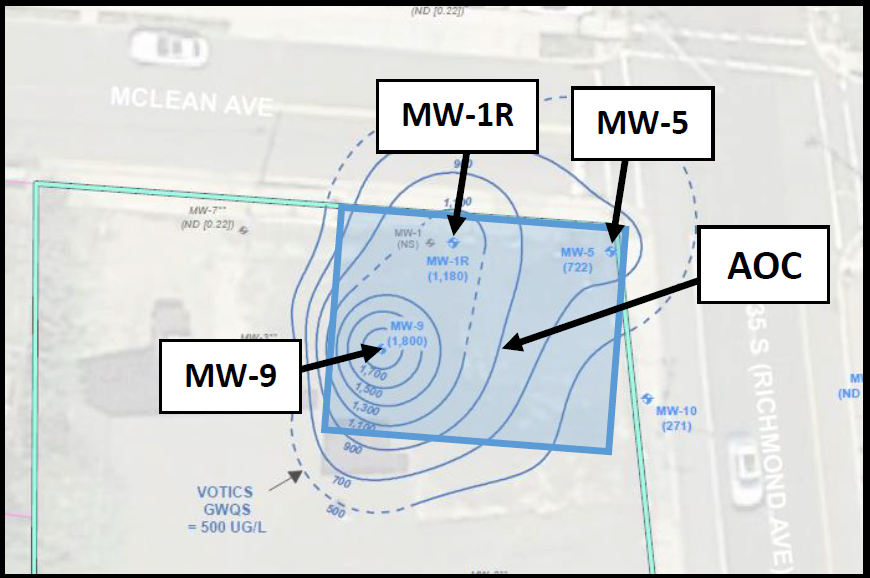

A former gas station located in Point Pleasant Beach, New Jersey was impacted with petroleum hydrocarbons due to leaks from underground storage tanks. The primary contaminants of interest (COIs) at the site were benzene, toluene, ethylbenzene, xylene (BTEX), trimethylbenzenes, and tentatively identified compounds (TICs) The area of concern (AOC) was approx. 2,600 sq ft with a target vertical interval from 7 to 11 feet below ground surface (ft bgs). The geology at the site is primarily a fine to medium grained sand with groundwater being encountered from 7 to 9 ft bgs. Provect-OX2™ was applied in situ to address the residual sorbed and dissolved phase petroleum hydrocarbon contaminant mass. Three primary monitoring wells were impacted within this AOC, including MW-1R, MW-5, and MW-9.

Remediation Plan

The remedial scope of work was developed by MidAtlantic Engineering Partners, LLC. and Provectus Environmental Products, Inc. (Provectus), which included the application of 7,550 lbs of Provect-OX2™ to the targeted AOC (Figure 1). Provect-OX2™ is a dual-functioning reagent blend that combines in situ chemical oxidation (ISCO) plus enhanced bioremediation (US Patent 9,126,245; patents pending). Provect-OX2™ rapidly oxidizes the organic contaminants present in soil and groundwater and provides long-term, sustained secondary bioremediation to manage residuals and prevent contaminant rebound. This is accomplished by using ferric iron (Fe III) as a safe and effective means of activating sodium and potassium persulfates, which quickly yields sulfate radicals (SO4-•) for chemical oxidation treatment. A pH buffer is also preblended with the Provect-OX2™ to offset any post-injection acidic pH conditions that are normally observed with traditional persulfate applications. The technology enhances subsequent utilization of sulfate and iron as terminal electron acceptors for facultative redox reactions to support secondary biodegradation of any residual contaminant mass.

The initial implementation plan included slurry injection of Provect-OX2™ at 12 temporary direct push points spaced on 15 ft. centers. Due to elevated injection pressures and heaving sands, a revised implementation plan was developed in the field after the first injection point was completed. The revised plan included the emplacement of Provect-OX2™ into augured boreholes. To ensure a sufficient radius of influence was achieved, a total of 13 boreholes were added to the remediation plan, yielding a total of 25 application locations in a grid-like pattern. The Provect-OX2™ application was implemented between July 22nd and July 27th, 2020. Figure 2 depicts the treatment AOC.

Treatment Program Results

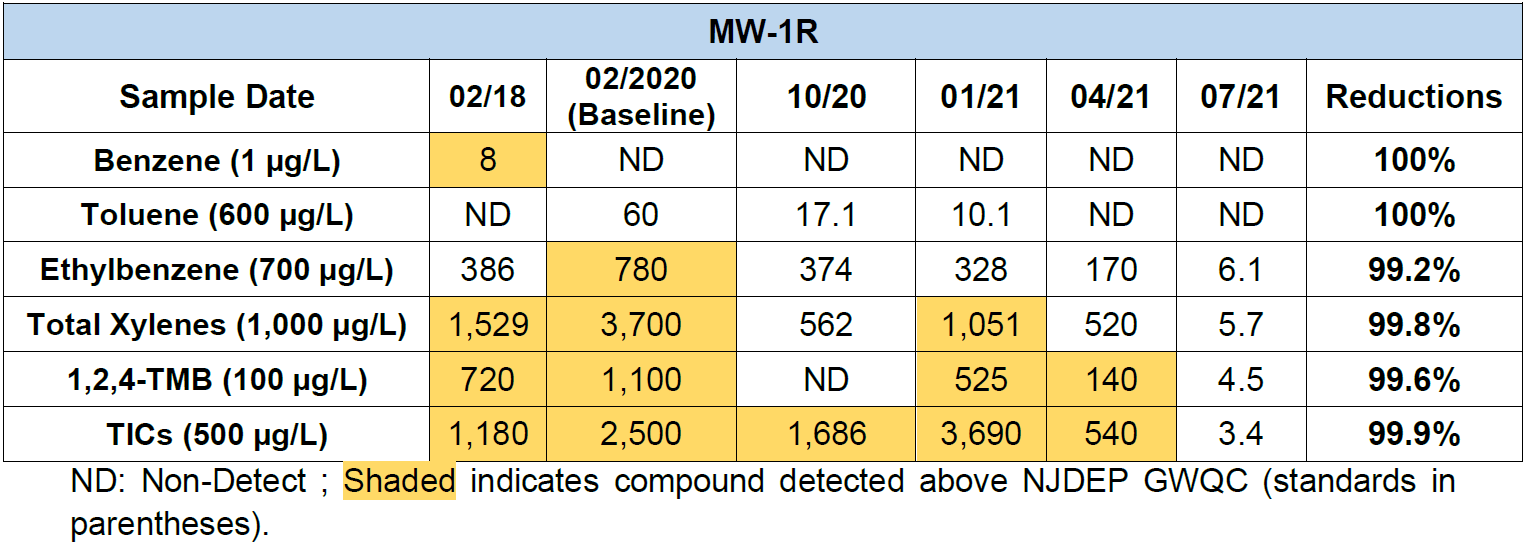

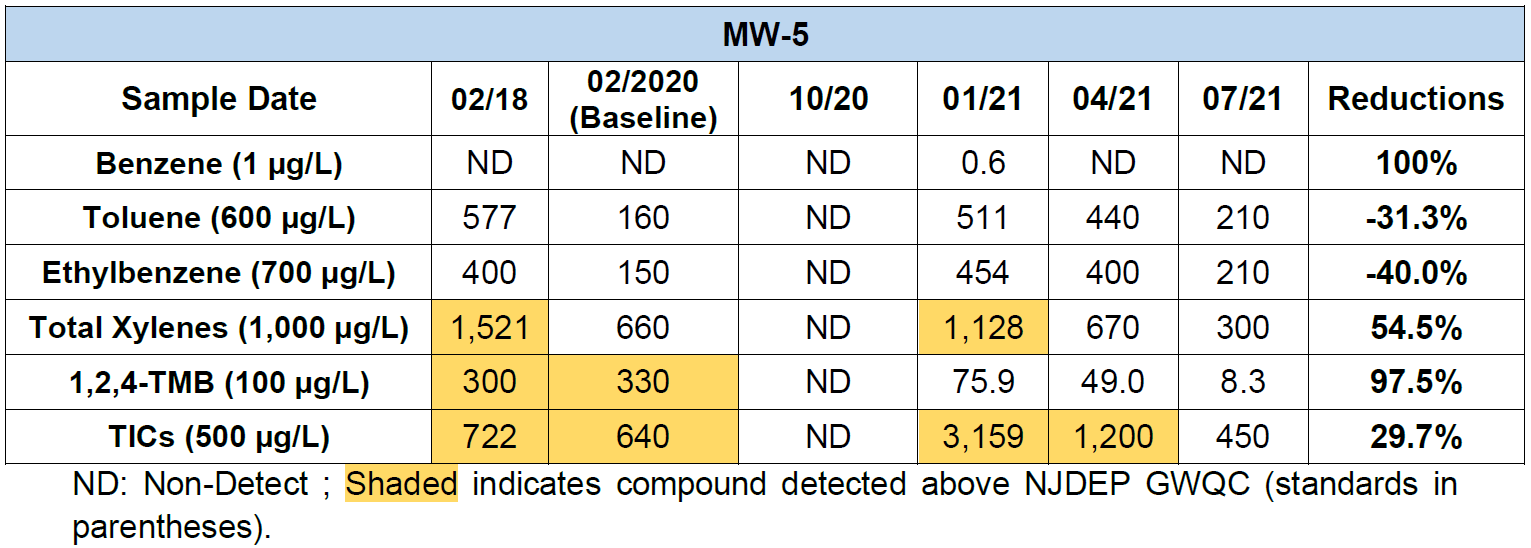

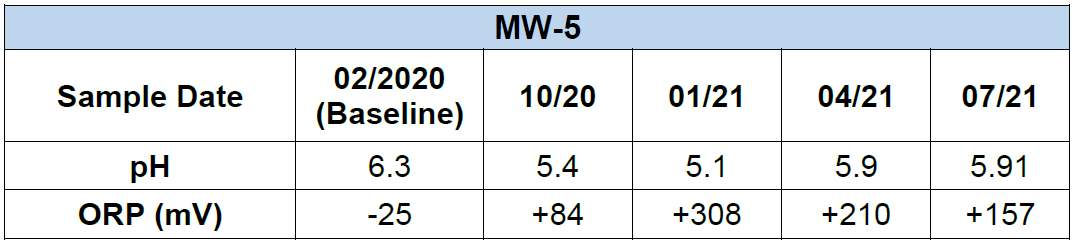

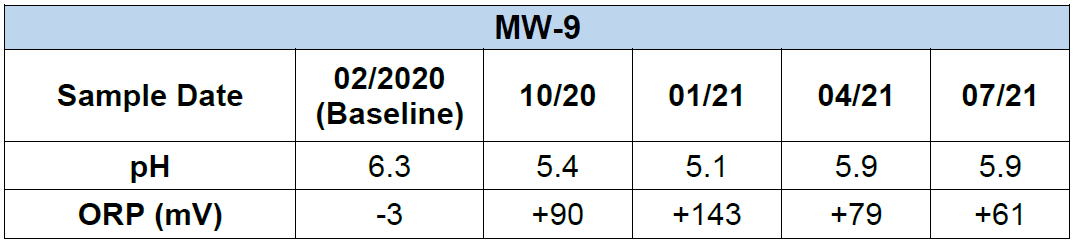

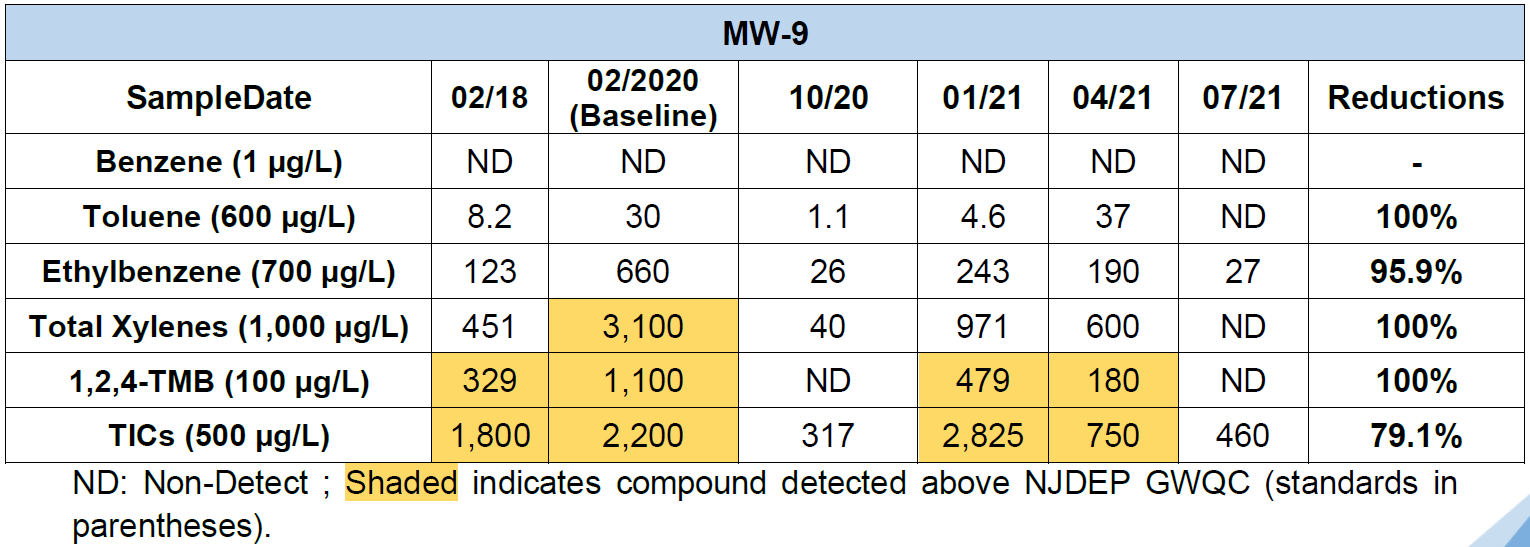

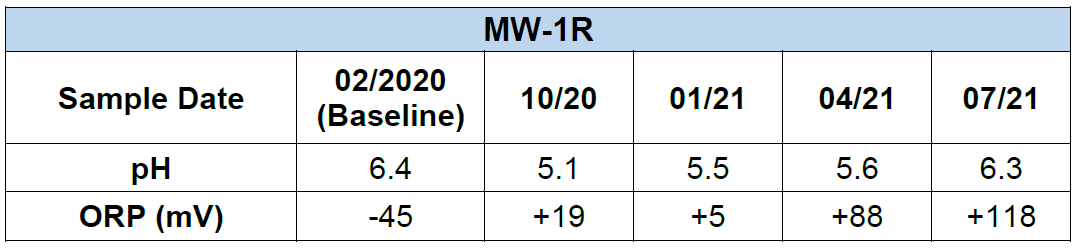

Post-application analytical data for the three target monitoring wells are presented below in Table 1, Table 2, and Table 3. MW-1R and MW-9 show the greatest contaminant reductions, with nearly all individual constituents being reduced by more than 95% and all COIs below New Jersey Groundwater Quality Standards (NJ GWQS). Additionally, the geochemistry data for the three target wells exhibit elevated ORPs 12 months after the Provect-OX2™ application including >+100 mV at MW-1R and MW-9. The included pH buffer component of the product offset production of sulfuric acid that is created due to persulfate activation (e.g., common persulfate applications exhibit pH <4). Field data for the monitoring wells are presented below in Table 4, Table 5, and Table 6. Changes in these field parameters are positive indicators of a successful field application and sufficient Provect-OX2™ distribution within the targeted area.

Table 3. VOC Data for MW-9

Table 4. Field Data for MW-1R

Table 4. Field Data for MW-1R

The targeted contaminants have reached the NJ GWQS within 1 year after the Provect-OX2™ application. We anticipate reductions will continue as the geochemistry remains ideal with ORPs still increasing due to continued potassium persulfate release. Furthermore, the secondary iron and sulfate enhanced bioremediation processes will remain active in the subsurface for several years after the ISCO reactions are complete.

Click Here for a site evaluation, conceptual remedial design, or material cost estimate with turn-key alternatives available upon request.