Provect-OX™ is an in situ chemical oxidation (ISCO) / enhanced bioremediation reagent that rapidly oxidizes a wide variety of organic constituents of interest (COI) present in impacted soil, sediment and groundwater (including chlorinated solvents, petroleum hydrocarbons, and pesticides) while uniquely supporting long-term, sustained, secondary bioremediation processes to manage residuals and prevent contaminant rebound (COI rebound is a common problem encountered with conventional ISCO technologies). This is accomplished by using ferric iron (Fe III) as a safe and effective means of activating persulfate which quickly yields sulfate and ferrate radicals for ISCO treatment. The process also enhances subsequent utilization of sulfate and iron as terminal electron acceptors for facultative redox reactions for improved biodegradation of any residual COIs. This combined remedy combines treatment mechanisms thereby allowing for more cost-efficient dosing of the product.

The use of ferric iron to activate persulfate was thoroughly described in 1958 (J.F. Henderson, McGill University, Montreal, Canada). However, the advanced activation catalyst is unique when considering its ability to enhance bioremediation processes over an extending period of time. Alternative methods of stimulating secondary biodegradation processes using oxygen release compounds (such as calcium or magnesium oxyhydroxide) are limited in that they will remain active for only a few months, after which time their oxygen release potential is exhausted. Iron, on the other hand, will remain active for many years. Moreover, oxygen release compounds inherently increase the local pH to extremely basic conditions (>10 pH units) which is simply not conducive to biological activity. Additional benefits include: i) Provect-OX will not generate excessive heat / off-gases, ii) nor will it mobilize heavy metals or lead to the generation of secondary impact issues such as elevated arsenic, chromium resulting from grossly elevated pH.

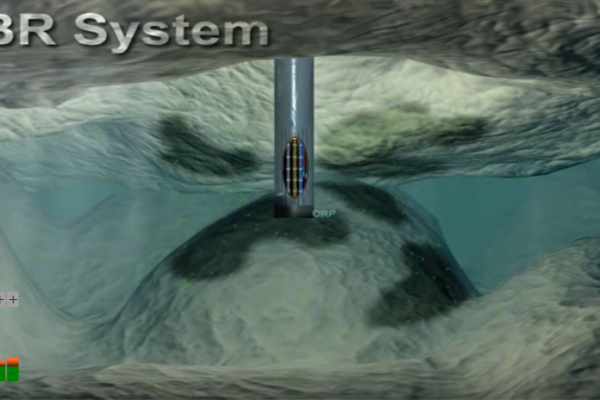

Provect-OX is a dry powder material that can be easily injected into a subsurface environment in a variety of ways, based on site-specific designs. Application methods include direct mixing, hydraulic fracturing, pneumatic fracturing, and direct push injection of slurries or liquids. Direct placement in trenches and excavations are also reliable application methods. Data from full-scale field applications will be presented to demonstrate effective in situ groundwater treatment for petroleum hydrocarbons (salinity levels variable) along with detailed cost analysis for the remedial actions.

Safer, More Effective ISCO Remedial Actions using Non-Extreme Persulfate Activation to Yield Sustained Secondary Treatment